Direct Roving Glass Fibres

Direct Roving Glass Fibres Specification

- Elasticity

- High

- Elongation

- Low

- Crimp Recovery

- Excellent

- Staple Length

- Continuous Filament

- Material

- Polyester

- Fiber Length

- Continuous

- Fineness (%)

- 0.8-2.0

- Pattern

- Dyed

- Use

- Filling Material

- Feature

- Anti-UV

- Linear Density (Tex)

- 300-2400

- Binder Type

- Silane

- Filament Diameter

- 13-24 micron

- Compatibility

- UP, VE, EP, PF Resins

- Thermal Resistance

- Up to 800C

- Packaging

- Palletized

- Grade

- Industrial

- Color

- White

- Tensile Strength

- >1200 MPa

- Moisture Content

- <0.15%

Direct Roving Glass Fibres Trade Information

- Minimum Order Quantity

- 35 Kilograms, ,

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Kilograms, , Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- South India

About Direct Roving Glass Fibres

Clients can avail from us Direct Roving which is an E-glass continuous fiber having a single end. This type of roving has compatibility with different materials like Polyester (UP), Vinylester (VE) and Epoxy (EP). Having unique abilities, this type of roving is used for laminates and profiles. Clients also use it for weaving and knitting purposes. Before shipping we pack Direct Roving using tacky-pack or shrinkage packing.

Suitable for:

-

Weaving

-

Filament winding

-

Pultrusion

-

Thermoplastics compounding

-

Multi-axial fabrics

Used in:

- FRP grating

- Fishing rod

- Umbrella pole

- Tent pole

Technical Specification

| Linear weight | Size Content | Moisture content | Fibre Diameter |

|---|---|---|---|

| 150 10% ,300 | 0.40 0.20 | 0.20 max. | 13 |

| 600 10% ,1200 | 0.40 0.20 | 0.20 max. | 16 |

Characteristics:

| Internal Diameter (mm) | 240 |

| Height (mm) | 250 |

| Net weight (Kilos) | 10 20 |

Superior Mechanical and Thermal Performance

With tensile strength exceeding 1200 MPa and thermal resistance up to 800C, these glass fibres assure robust performance in demanding industrial environments. Their high elasticity and low elongation further enhance material durability, making them ideal for structural applications.

Versatile Resin Compatibility for Composite Benefits

The silane binder ensures reliable adhesion and seamless integration with Unsaturated Polyester, Vinyl Ester, Epoxy, and Phenol Formaldehyde resins. This versatility allows manufacturers to use the fibres in a wide array of composite products, optimizing strength and longevity.

FAQs of Direct Roving Glass Fibres:

Q: How are Direct Roving Glass Fibres typically used in industrial applications?

A: These fibres are primarily utilized as filling or reinforcing materials in composite fabrication due to their continuous length, high strength, and excellent elasticity. They enhance the mechanical properties of end products such as panels, pipes, and automotive parts.Q: What is the process for integrating these glass fibres with resins?

A: The fibres are laid or wound into molds and then impregnated with compatible resins like UP, VE, EP, or PF. The silane binder facilitates strong bonding between the fibre and resin, followed by curing to produce durable composite structures.Q: When should these fibres be selected for a project?

A: These fibres are ideal when projects demand high-strength reinforcement, thermal tolerance up to 800C, and compatibility with various resins. They suit both load-bearing and high-temperature industrial solutions.Q: Where are these Direct Roving Glass Fibres sourced from?

A: They are manufactured and supplied in India by reputable companies specializing in industrial-grade fibre production, ensuring consistent quality and reliable supply for domestic and international clients.Q: What benefits do the anti-UV properties and high crimp recovery offer?

A: Anti-UV features protect composites from degradation due to sunlight exposure, while excellent crimp recovery ensures the fibres regain shape after deformation, improving the resilience and lifespan of finished materials.Q: How does the packaging ensure product integrity during transportation?

A: The palletized packaging secures large quantities of fibres, preventing damage, moisture uptake (kept below 0.15%), and maintaining structural integrity from manufacturer to end-user.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Glass Fibres Category

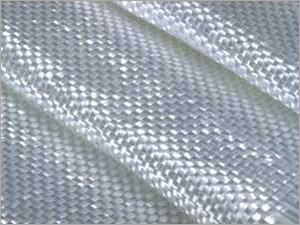

Woven Roving Fiberglass Mat

Price 200 INR / Kilograms

Minimum Order Quantity : 35 Kilograms

Use : Filling Material, Spinning

Feature : AntiUV

Material : Polyester

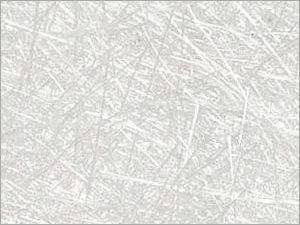

Chopped Strand Mat

Price 140 INR / Kilograms

Minimum Order Quantity : 35 Kilograms, ,

Use : Filling Material

Feature : AntiUV

Material : Polyester

Chopped Strands

Price Range 120.00 - 150.00 INR / Kilograms

Minimum Order Quantity : 35 Kilograms

Use : Filling Material

Feature : AntiUV

Material : Polyester

Chopped Strand Emulsion

Price Range 120.00 - 150.00 INR / Kilograms

Minimum Order Quantity : 35 Kilograms

Use : Filling Material, NonWoven Fabric

Feature : AntiUV

Material : Polyester

"We mainly deals in Karnataka, Tamil Nadu, Kerala, Telangana, Andhra Pradesh, Pundicherry, Goa only."

Corporate Office

NO.233, Rahul Building,

HBCS 4th Stage, Rajajinagar Industrial Town,

6th Cross, Rajajinagar

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free